A self-contained, fully instrumented, educational singleshaft gas turbine with reheat. Powered by kerosene, the experimental abilities of this high-quality apparatus enable comprehensive practical investigations into the principles, and performance of single-shaft gas turbines with reheat.

This product helps students to understand the use of this “engine” with additional exhaust nozzle control, on practical applications such as jet aircraft.

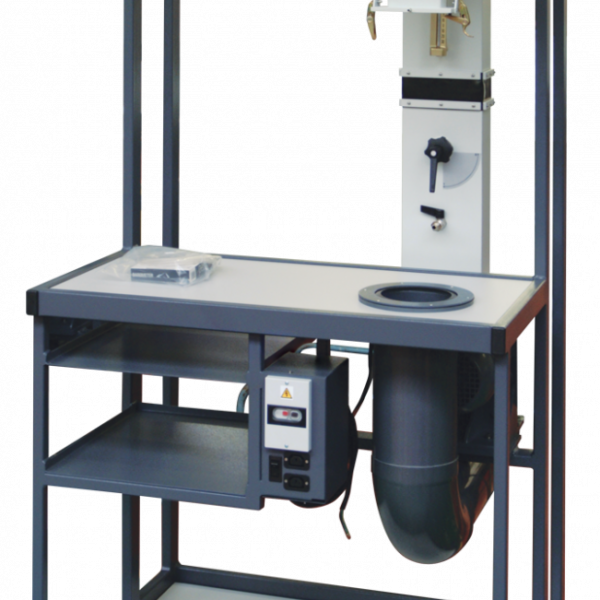

A steel frame holds a gas generator, combustion chamber, oil and fuel tanks, pumps, ancillaries and guards. Above these is an instrumentation and control panel with schematic diagram. The clearly labelled control panel with mimic diagram includes the instrument displays, controls and warning lights. Air passes into an air box, through a calibrated nozzle into a compressor, then into the combustion chamber. A pump transfers fuel from the fuel tank to spray through a special nozzle into the combustion chamber. A high-energy spark ignites the air and fuel mixture, that flows to a radial flow turbine, then to the reheat section. This increases the temperature and velocity of the gas. It then passes through a variable area propelling nozzle. The exhaust gases then discharge to a suitable exhaust system. The combustion chamber gives excellent combustion, low pressure loss and good flame stability over a wide range of conditions. A fuel flow control valve on the instrumentation and control panel regulates the turbine speed. This design reduces the possibility of overspeed. A separate control adjusts the fuel flow to the reheat section. A second high-energy spark in the reheat section ignites the reheat fuel. This creates a secondary burn (or afterburn), using some of the remaining oxygen in the hot exhaust gases leaving the turbine.

The equipment has an oiling system including filters and water-cooled oil. A PLC (programmable logic controller) controls the turbine start up and shut down. For protection of the equipment and user, it shuts down the turbines if the user makes an error. It also switches on cooling fans after running. Digital and analogue indicators show all the important readings from the sensors around the equipment, such as pressures, temperatures, fuel flow and level.

This equipment connects to your computer (computer not supplied) and includes dedicated, user-friendly data acquisition software. This allows students to display, graph and analyse all relevant variables, and save their results for later analysis. The data acquisition system includes adaptors and leads, and the software is supplied on CD-ROM.

Supplied with the equipment is a detailed textbook that covers the theory and use of gas turbines.