A bench-top unit to demonstrate free and forced vibrations

of two mass-beam systems:

1. A ?rigid? beam with a pivot at one end and a spring at

the other ? the spring provides the elasticity

2. A ?flexible? pinned ? pinned beam with a pivot at one

end and a roller pivot at the other ? the beam itself

provides the elasticity

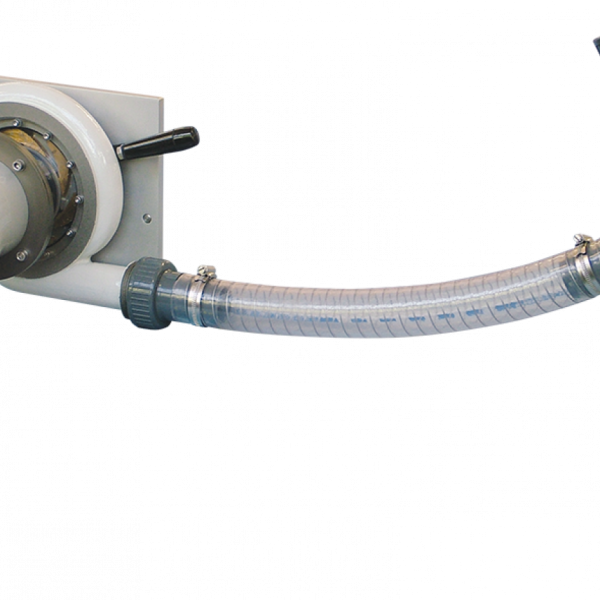

A rigid and heavy steel frame holds the systems. The frame

has a low natural frequency, so the vibrations of the

systems do not affect it. The frame has two sections: an

experiment ?window? to the right and a control panel to

the left. The experiment window contains the beam,

spring and other parts used in the experiments.

TecQuipment carefully designed the equipment so that all

experiments use the same beam. This gives a simple and

quick system set up and changeover time. The beam is of

high-grade ground steel, and the pivots use high-quality

ball races for lowest friction and incidental damping.

Students may vibrate the systems manually. They may also

force the vibrations using a high-quality variable speed

servomotor driving a rotating offset mass – forming an

?exciter?. The servomotor has its own encoder and

advanced controller for accurate speed regulation. This

gives minimal cyclical variation due to inertial load

variations.

A non-contacting sensor measures beam displacement.

The sensor has no physical contact with the oscillating

system, for negligable damping.

An accelerometer built into the exciter assembly works to

show the phase relationship between beam displacement

and acceleration. It also helps to compare measured

acceleration with that derived from the displacement using

the software.

The unit includes a variable-area viscous dashpot damper,

for use with a non-toxic fluid (supplied) of stable viscosity.

This ensures repeatable results over a range of ambient

temperatures.

An encoder linked to the rotating exciter mass measures its

dynamic position. This helps to measure the relationship

between the applied force and the position of the beam,

showing phase lag with different damping values.

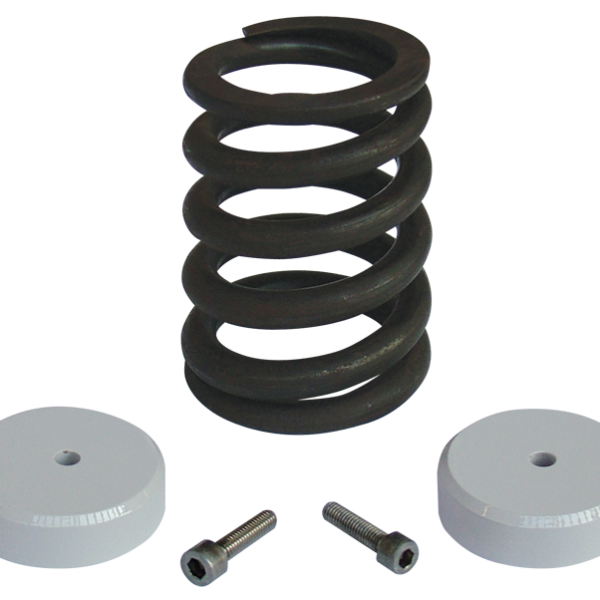

TecQuipment include a vibration absorber with the

equipment. When fixed to the beam it adds a second

degree of freedom to the complete system. This

demonstrates the typical behaviour of a 2 degree of

freedom (2DOF) system. Students learn how to ?tune? the

vibration absorber to eliminate the oscillations of the main

beam – a special case of a 2DOF system and an alternative

method to damping.

To help store small parts and tools, TecQuipment supply a

storage tray with the equipment.

The control panel houses the servomotor controller and

manual controls, alongside a digital display of the motor

speed in units of rev.min?1, rad.s?1 and frequency in Hz. It

also provides outputs of the displacement, acceleration,

encoder (offset mass) position, and motor speed. These

outputs are calibrated and scaled to work directly with

TecQuipment?s VDAS? (mkII) system.

The output signals connect to the VDAS? interface which

converts them for connection to a suitable PC (not

supplied).

The VDAS? (mkII) software includes functions to display

live plots of first and second derivatives, to show velocity

and acceleration waveforms based on the displacement

signal. Advanced features of the software allow signal

smoothing, reference plots and a tool to help measure the

free vibration damping coefficient.

TecQuipment have specifically designed the TM1016 to

work with VDAS. However, the sensor and trigger outputs

may be connected to your own data acquisition system or

oscilloscope if desired.

Hot

FREE AND FORCED VIBRATIONS

Allows Students to investigate the free and forced vibration of a rigid beam and spring, and a simply supported beam

| Brand |

TecQuipment |

|---|---|

| Product type |

Experiment |

| VDAS |

YES |

Description

SKU:

TM1016

Categories: Engineering Experiments TecQuipment, Theory of Machines

Tag: Theory of Machines